Service

Service Intervals

Every 10 Hours

• If operating in dry conditions, clean debris from mower.

Every 25 Hours

Every 100 Hours

Every 500 Hours

Grease

The following greases are preferred:

• John Deere Multi-Purpose SD Polyurea Grease

• John Deere Multi-Purpose HD Lithium Complex Grease

If not using any of the preferred greases, be sure to use a general all-purpose grease with an NLGI grade No.2 rating.

Wet or high speed conditions may require use of a special-use grease. Contact your Servicing dealer for information.

Gear Oil

Use oil viscosity based on the expected air temperature range during the period between oil changes.

John Deere GL-5 Gear Lubricant is recommended.

Other oils may be used if they meet one or more of the following:

• API Service Classification GL-5.

• Military Specification MIL-L-2105D.

• Military Specification MIL-L-2105C.

• Military Specification MIL-L-2105B.

Oils meeting Military Specification MIL-L-10324A may be used as arctic oils.

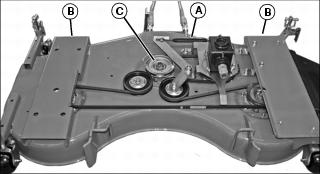

Lubricating Mower

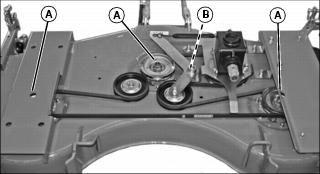

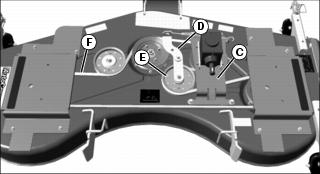

Picture Note: 60D mower shown.

1. Lubricate three grease fittings (A) on sheaves with recommended grease.

2. Lubricate grease fitting (B) on tensioner pulley with recommended grease.

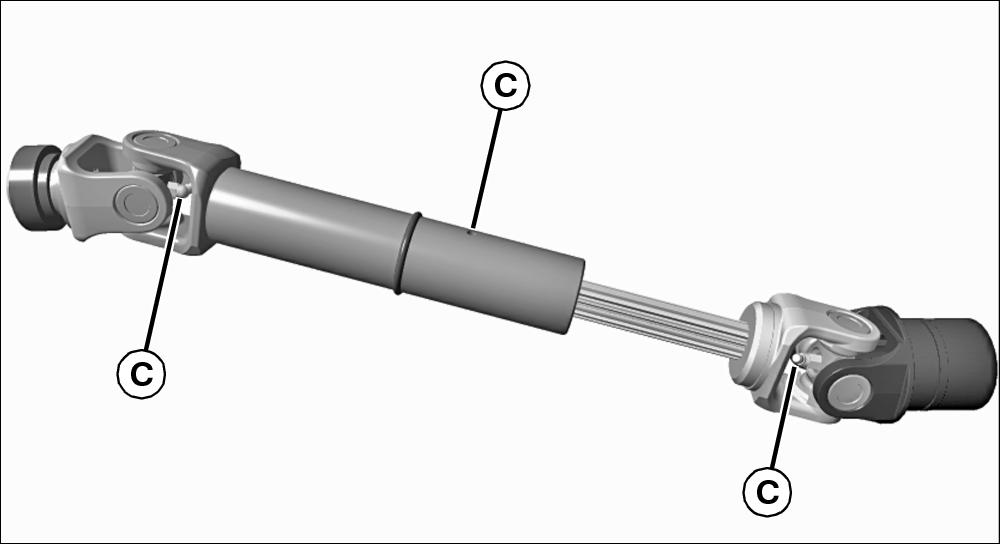

3. Lubricate three grease fittings (C) on mid PTO with recommended lubricant.

Servicing Gearbox

Checking Oil Level

1. Remove plug from one side of gearbox.

2. Oil level should be even with bottom edge of plug hole.

3. If oil is low, add recommended oil.

Changing Oil

1. Remove gearbox bracket with gearbox. See Removing Belt in SERVICE.

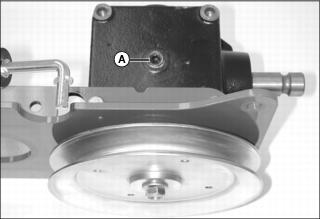

2. Remove plug (A) on both sides of gearbox.

3. Lift and turn gearbox bracket on side to drain oil from gearbox.

4. Route belt around gearbox sheave as you install gearbox bracket on five bolts. See Installing Belt in SERVICE.

5. Following remaining instructions in Installing Belt in SERVICE to install gearbox and rod.

6. Add recommended oil to bottom edge of plug hole in gearbox.

Servicing Mower Belt

Removing Belt

2. Clean area around and under ramps.

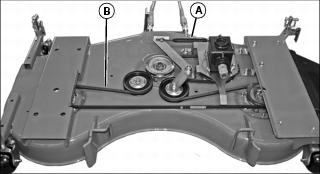

Picture Note: 60D mower shown.

• Remove spring (A) to relieve belt tension.

Picture Note: 72D mower shown.

• Remove the gearbox support (C) by removing four nuts.

• Remove the nut, washer and tensioner (D).

• Remove the bolt and hardware retaining the tensioner pulley (E) then remove bolt.

Installing Belt

1. Install belt around sheaves and route as shown.

3. 72D: Install tensioner pulley, tensioner and gearbox support.

Servicing Mower Blades

Checking for Bent Mower Blades

1. Park machine on a level surface, not on a slope.

7. Wait for engine and all moving parts to stop before you leave the operator’s seat.

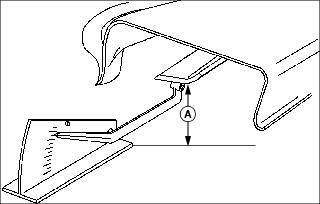

9. Measure the distance (A) from blade tip to level surface with a ruler or a leveling gauge available at your John Deere dealer.

10. Rotate blade 180° and measure the distance between other end of blade and surface.

11. Check all blades. Install new blade if difference between measurements is more than 3 mm (1/8 in.).

Removing Mower Blades

1. Park machine safely. (See Parking Safely in SAFETY.)

3. Use a suitable lifting device to raise mower to gain access to blades.

4. Insert wood block between blade and mower to prevent blade from turning when removing bolt.

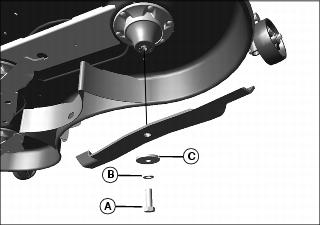

5. Remove bolt (A), washer (B), washer (C) and blade.

Installing Mower Blades

1. Install blade with cutting edge toward the ground.

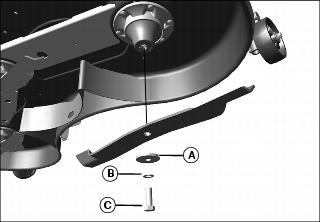

2. Install washer (A), washer (B) and bolt (C).

3. Insert wood block between blade and mower to prevent blade from turning when tightening bolt. Tighten to 122 N•m (90 lb-ft).

Sharpening Blades

1. Sharpen blade with grinder, hand file or electric blade sharpener.

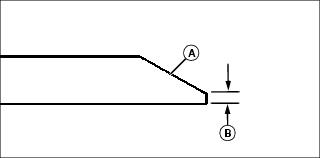

• Keep original bevel (A) when grinding.

• Blade should have 0.40 mm (1/64 in.) cutting edge (B) or less.

2. Balance blade before installing.

Balancing Blades

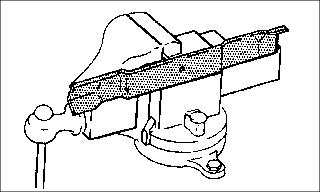

2. Put blade on a nail in a vice or in a vertical wall stud. Turn blade to horizontal position. If blade is not balanced, heavy end of blade will drop.

3. Grind bevel of heavy end. Do not change blade bevel.

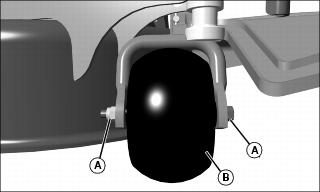

Replacing Wheels

1. Park machine on a level surface, not on a slope.

7. Wait for engine and all moving parts to stop before leaving operator’s seat.

IMPORTANT: Avoid damage! Do not overtighten wheel hardware. Overtightening hardware will cause damage to bushing. |

9. Install new wheel (B) with hardware.

Replacing Sheaves

Picture Note: 60D mower shown. 72D mower sheaves have four nuts instead of one.

1. Remove spring (A) to relieve belt tension.

2. If necessary, remove drive over ramp (B).

3. 60D mower: Remove center bolt (C) on sheave to be replaced.