Service Transmission

Transmission and Hydraulic Oil

IMPORTANT: Avoid damage! Transaxle is filled with John Deere HY-Gard™ (J20D) transmission oil at the factory. DO NOT mix oils. |

Do not use type “F” automatic transmission fluid.

Use Low Viscosity Hy-Gard™ (J20D) transmission oil.

John Deere Low Viscosity Hy-Gard transmission oil is specially formulated for operation below -18provide maximum protection for the hydraulic system.

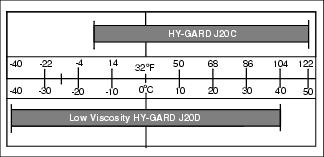

Use oil viscosity based on the expected air temperature range during the period between oil changes.

IMPORTANT: Avoid damage! Use recommended oil only. Do not use engine oil or “Type F” automatic transmission fluid. |

Other oils may be used if they meet John Deere standard JDM J20D or J20C.

Checking Front Axle Oil Level

IMPORTANT: Avoid damage! Allow oil one hour to settle before checking level to ensure accurate dipstick reading. Repeat oil level check after several hours of operation. |

1. Park machine safely. (See Parking Safely in the SAFETY section.) Allow machine to cool down for at least one hour.

IMPORTANT: Avoid damage! Dirt and debris in oil may cause damage to the transaxle. Clean area around opening before removing dipstick. |

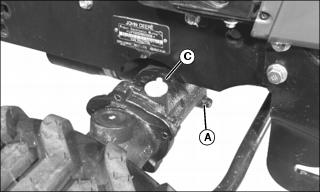

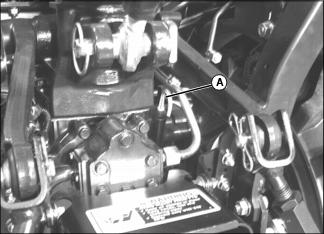

2. Loosen and remove dipstick (A) located on right side of front axle.

3. Wipe dipstick clean with a rag. Install dipstick but do not tighten. Allow dipstick to rest on top of threads.

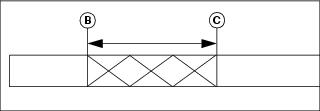

4. Remove dipstick. Oil level should be between high (B) and low (C) levels on dipstick. If oil level is low:

a. Add recommended oil through dipstick fill opening until oil level is correct.

b. Install and tighten dipstick.

5. Check front axle oil level again after the first several hours of operation.

Changing Front Axle Oil

1. Operate machine to warm front axle oil.

2. Park machine safely. (See Parking Safely in the SAFETY section.)

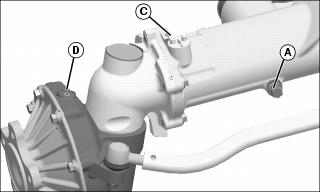

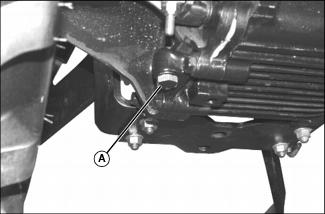

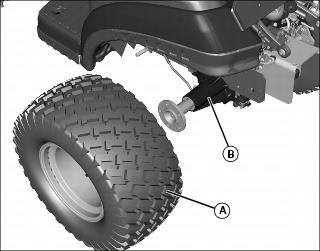

3. Position drain pan under differential drain plug (A).

NOTE: For draining purposes, front axle contains approximately 2.8 L (3.0 qt) of oil.

4. Remove differential drain plug and allow oil to drain.

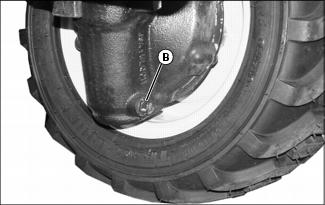

5. Position drain pan under each front axle drain plug (B).

6. Remove both drain plugs and allow oil to drain.

7. Install and tighten both drain plugs after all oil has drained.

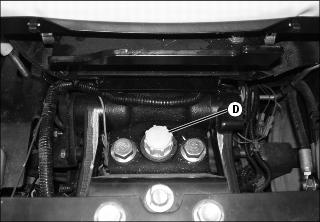

8. Remove dipstick (C) located on right side of front axle and vent plug (D).

9. Add approximately 2.8 L (3.0 qt) of recommended oil through dipstick fill opening until oil level is correct.

10. Install and tighten dipstick.

IMPORTANT: Avoid damage! Allow oil one hour to settle before checking level to ensure accurate dipstick reading. Repeat oil level check after several hours of operation. |

11. Check front axle oil level.

Checking Transmission Oil Level

1. Park machine safely. (See Parking Safely in the SAFETY section.) Allow machine to cool down for at least one hour.

IMPORTANT: Avoid damage! Dirt and contamination can enter transmission when checking oil level. Clean area around dipstick before removing. |

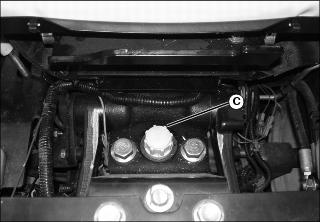

2. Pull to remove dipstick (A), located at the right side of the transmission. Wipe with a clean cloth.

5. Check oil level on dipstick. Oil level should be between levels (B) and (C) on dipstick.

• Add recommended oil through fill opening until oil level is correct.

7. If oil is above top mark on the dipstick, drain to proper level.

9. Install and tighten filler cap.

Changing Transmission Oil and Filter

1. Run engine a few minutes to warm the transmission oil.

2. Park machine safely. (See Parking Safely in the SAFETY section.)

NOTE: For draining purposes, the transmission contains approximately 12.3 L (13 qt) of oil.

3. Position drain pan under transmission drain plug (A). Remove plug and allow oil to drain completely.

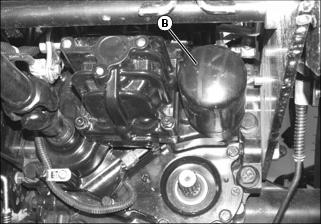

4. Position drain pan under transaxle oil filter (B). Remove and discard filter. Allow residual oil to drain completely.

5. Put a film of clean transmission oil on seal of new filter.

6. Fill the filter 1/3 - 1/2 full of oil.

7. Install filter and turn clockwise until gasket makes contact with the mounting surface. Tighten 1/2 - 3/4 turn after gasket contact.

8. Install and tighten drain plug.

10. Add approximately 12.3 L (13 qt) of preferred transmission oil or equivalent into fill opening.

12. Start engine. Check for oil leaks.

14. Check transmission oil level. Add oil if necessary.

Remove and Install Oil Suction Screen

1. Park the machine safely. (See Parking Safely in the SAFETY section.)

2. Remove backhoe, if installed.

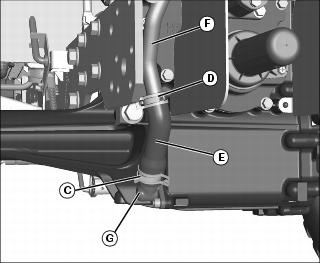

3. Raise rear of machine, and remove left rear wheel (A).

4. Lower machine onto jack stand under left side of transmission (B).

5. Place a drain pan under left side of transmission. Drain transmission.

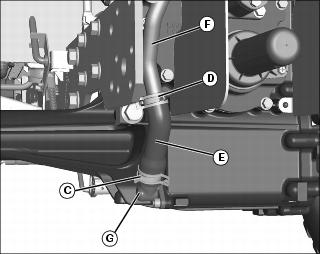

6. Raise bottom hose clamp (C), and lower top hose clamp (D) onto hose (E).

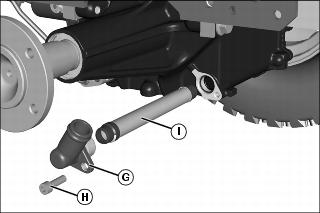

7. Remove hose (E) from suction pipe (F) and lower manifold (G).

8. Remove bolt (H). securing lower manifold to transmission case.

NOTE: If suction screen does not come out with the lower manifold, reach in and remove screen from transmission. Be certain all O-Rings remain on assemblies.

9. Remove lower manifold (G) and suction screen (I).

NOTE: Depending upon your machine, you may have one, two, or four magnets in screen.

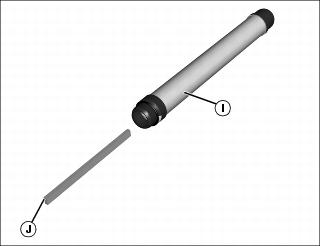

10. Clean the suction screen (I). Remove the magnet(s) (J) from the screen. Clean magnet(s) and install into screen.

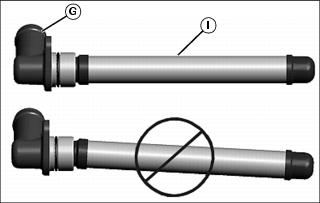

11. Lubricate and install suction screen (I) to lower lower manifold (G). Make sure screen is fitted straight into elbow to aide proper alignment to transmission opposite side cover.

NOTE: Suction screen must remain perpendicular to lower manifold as shown below for it to align properly into flange area (K) on opposite side of transmission.

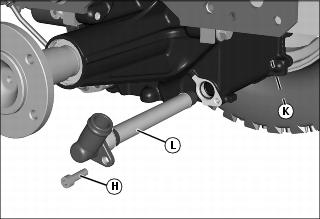

12. Install suction screen assembly (L) into transmission. Make sure end of screen fits into socket inside transmission right side cover.

13. Install bolt (H). Tighten bolt to 28 N•m (248 lb-in.).

NOTE: If upper suction pipe (F) was removed from hydraulic pump, replace O-ring before installing pipe. Tighten bolts to 11 N•m (97 lb-in.)

14. Install hose (E) onto suction pipe (F) and lower manifold (G). Secure upper with upper clamp (D) and lower clamp (C).

15. Install left wheel onto machine. Tighten wheel bolts to 120 N•m (89 lb-ft).