Introduction

Product Identification

Safety

Operating

Avoid Damage to Plastic and Painted Surfaces

Operator Station (Hydrostatic Models)

Operator Station (Gear Models)

Safety Interlock System Checkout Procedure (Gear Models)

Safety Interlock System Checkout Procedure (Hydrostatic Models)

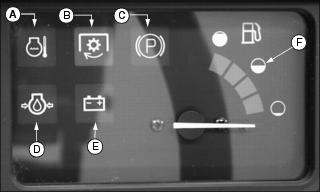

Understanding Instrument Panel - Right Side

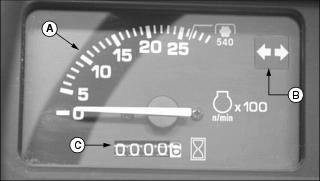

Understanding Instrument Panel - Left Side

Using Brake Pedals (Gear Models)

Using Brake Pedals (Hydrostatic Models)

Using Park Brake (Gear Models)

Using Park Brake (Hydrostatic Models)

Selecting a Range or Gear (Gear Transmission)

Selecting a Range (Hydrostatic Transmission)

Driving Tractor (Hydrostatic Model)

Using the Cruise Control (Hydrostatic Models Only)

Using Mechanical Front Wheel Drive (MFWD)

Using the Power-Take-Off (PTO) Safely

Using the Rear and Mid Power-Take-Off (PTO) (Gear Models) (Operator On Seat)

Using the Rear and Mid Power-Take-Off (PTO) (Hydrostatic Models) (Operator On Seat)

Using the Rear Power-Take-Off (PTO) (Operator Off Seat)

Leveling Attachment Front-to-Rear

Leveling Attachment Side-to-Side

Adjusting Attachment Side-to-Side Sway

Using Speed of Drop/Lock Valve

Using the Rockshaft Control Lever

Using Optional Hydraulic Selective Control Valve (SCV)

Using Selective Control Valve (SCV) Lock Lever

Connecting Attachment Hydraulic Hoses

Determining Maximum Rear Ballast

Using Optional Rear Cast Iron Wheel Weights

Using Optional Rear Ballast Box

Determining Maximum Front Ballast

Replacement Parts

Service Intervals

Service Lubrication

Service Engine

Service Transmission

Service Electrical

Service Miscellaneous

Troubleshooting

Storage

Assembly

Specifications

Warranty

John Deere Quality Statement

Service Record

Operating

Daily Operating Checklist

o Check transmission oil level.

o Check coolant level on liquid cooled engine.

o Remove grass and debris from machine.

o Check area below machine for leaks.

Avoid Damage to Plastic and Painted Surfaces

· Do not wipe plastic parts unless rinsed first.

· Insect repellent spray may damage plastic and painted surfaces. Do not spray insect repellent near machine.

· Be careful not to spill fuel on machine. Fuel may damage surface. Wipe up spilled fuel immediately.

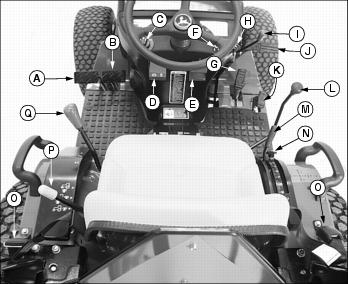

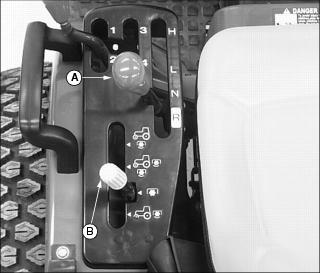

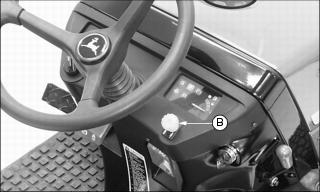

Operator Station (Hydrostatic Models)

F - Power Take Off (PTO) Switch

I - Engine Speed Hand Throttle

L - Selective Control Valve (SCV) Lever

N - Rockshaft Adjustable Depth Stop Knob

P - Power Take Off (PTO) Control Lever

Q - Transmission Range Shift Lever

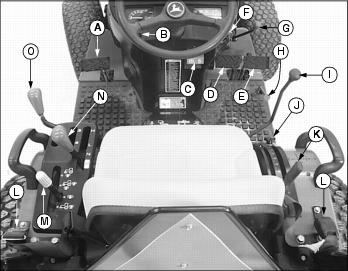

Operator Station (Gear Models)

G - Engine Speed Hand Throttle

H - Engine Speed Foot Throttle

I - Selective Control Valve (SCV) Lever

J - Rockshaft Adjustable Depth Stop Knob

M - Power Take Off (PTO) Control Lever

N - Transmission Range Shift Lever

O - Transmission Gear Shift Lever

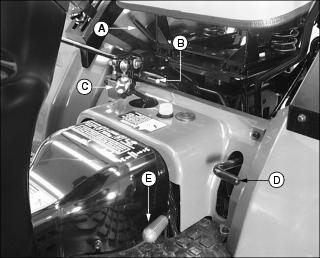

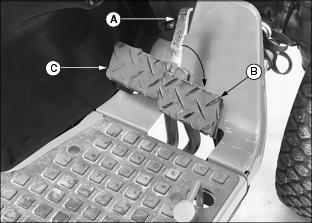

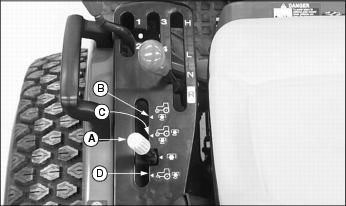

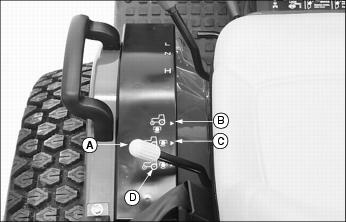

Floor Panel Controls

A - Operator Seat Adjustment Lever

B - Selective Control Valve (SCV) Lock

C - Rockshaft Rate-of Drop Control Knob

D - Differential Lock Pedal (On right side for gear models.)

E - Mechanical Front Wheel Drive (MFWD) Control Lever

Adjusting Seat

3. Slide seat forward or rearward to desired position.

4. Release lever to lock seat in position. Make sure all controls can be easily accessed.

Adjusting Seat Belt

Fasten Seat Belt

1. Remove seat belt ends from brackets mounted on each side of operator seat.

2. Connect both ends of seat belt. Tighten or loosen seat belt until firmly held onto the seat.

Release Belt

1. Press red button on buckle to release seat belt ends.

2. Install seat belt ends in fender mounting brackets when seat belts are not being used.

Safety Interlock System Checkout Procedure (Gear Models)

Use the following checkout procedure to check for normal operation of machine.

If there is a malfunction during one of these procedures, Do not operate machine. See your John Deere dealer for service.

Perform these tests in a clear open area. Keep bystanders away.

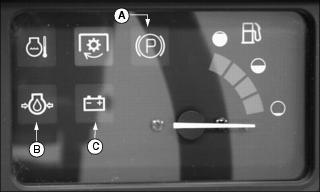

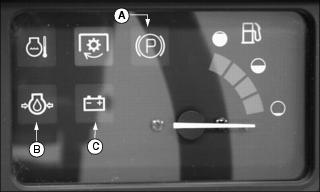

Test 1- Operation of Instrument Panel Indicator Lights

3. Move 2-speed range and direction lever into the N (neutral) position.

4. Move the PTO control lever to the disengaged/off position.

5. Turn key switch to the ON position.

· Look: The park brake indicator light (A) must illuminate and flash. The engine oil pressure indicator light (B) and alternator/battery charging light (C) must illuminate.

· Listen: The engine fuel shut-off solenoid will engage with a click.

6. If any of the indicators do not illuminate, see the service electrical section. If any indicators fail to light after light bulb replacement, see your John Deere dealer.

Test 2 - Neutral Start Switch

2. Depress clutch pedal completely.

3. Move the transmission range shift lever to the H (high), L (low) or R (reverse) position.

4. Turn key switch to START position.

5. Turn key to OFF position and move transmission to the N (neutral) position.

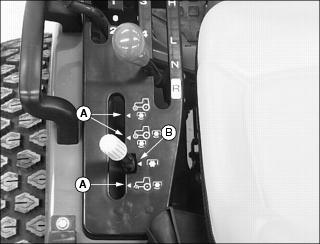

Test 3 - Power-Take-Off (PTO) Switch

2. Depress clutch pedal completely.

3. Move the PTO control lever to any engaged/on position (A). Slowly release the clutch pedal.

4. Turn key to the START position.

5. Depress clutch pedal completely and move the PTO control lever to the disengaged/off position (B).

6. Turn key to the OFF position.

Test 4 - Seat Switch/PTO Interface

2. Move 2-speed range and direction lever into the N (neutral) position.

3. Make sure the park brake is locked.

5. Depress clutch pedal completely and move the PTO control lever to any engaged/on position.

6. Raise up from operator's seat. Do not dismount tractor.

7. Engine shut-off solenoid must de-energize in 1/2 second, causing the engine to stop.

Test 5 - Seat Switch

2. Move the PTO control lever to the disengaged/off position.

3. Make sure the park brake is locked.

4. Start tractor engine. Set engine speed at 2650 rpm.

5. Depress clutch pedal completely.

6. Move the transmission range shift lever to the H (high), L (low) or R (reverse) position.

7. Raise up slightly off from operator's seat while depressing clutch pedal all the way down.

Test 6 - Transmission Range Shift Lever Switch

2. Make sure the park brake is locked.

4. Move the transmission range shift lever to the H (high), L (low) or R (reverse) position.

5. Turn key to the START position.

Safety Interlock System Checkout Procedure (Hydrostatic Models)

Use the following checkout procedure to check for normal operation of machine.

If there is a malfunction during one of these procedures, Do not operate machine. See your John Deere dealer for service.

Perform these tests in a clear open area. Keep bystanders away.

Test 1- Operation of Instrument Panel Indicator Lights

3. Return hydrostatic travel pedals to neutral position.

4. Push PTO knob down to the disengaged/off position.

5. Turn key switch to the ON position.

· Look: The park brake indicator light (A) must illuminate and flash. The engine oil pressure indicator light (B) and alternator/battery charging light (C) must illuminate.

· Listen: The engine fuel shut-off solenoid will engage with a click.

6. If any of the indicators do not illuminate, see the service electrical section. If any indicators fail to light after light bulb replacement, see your John Deere dealer.

Test 2 - Neutral Start Switch

2. Push PTO knob down to the disengaged/off position.

3. Depress completely forward or reverse hydrostatic drive pedal.

4. Turn key switch to START position.

5. Turn key switch to the OFF position.

Test 3 - Power-Take-Off (PTO) Switch

2. Pull PTO knob up to the engaged/on position.

3. Turn key to the START position.

4. Push PTO knob down to the disengaged/off position.

5. Turn key switch to the OFF position.

Test 4 - Seat Switch/PTO Interface

2. Return hydrostatic travel pedals to neutral position and lock the park brake.

4. Pull PTO knob up to the engaged/on position.

5. Raise up from operator's seat. Do not dismount tractor.

6. Engine shut-off solenoid must de-energize in 1/2 second, causing the engine to stop.

Test 5 - Seat Switch

2. Return hydrostatic travel pedals to neutral position and lock the park brake.

4. Move the 2-speed range lever to the H (high) or L (low) position.

5. Raise up from operator's seat. Do not dismount tractor.

6. Engine shut-off solenoid must de-energize in 1/2 second, causing the engine to stop.

Test 6 - Transmission Range Shift Lever Switch

2. Make sure the park brake is locked.

3. Move the transmission range shift lever to the H (high) or L (low) position.

4. Turn key to the START position.

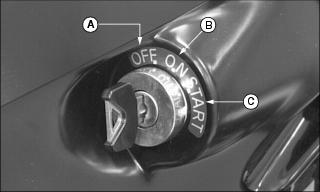

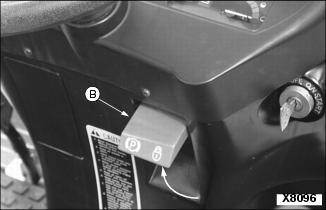

Using Ignition Switch

A - OFF Position - In this position the engine will not run.

B - ON Position - Move key from OFF to this position and the engine oil pressure light and battery charging light will turn on. You will also hear the engine fuel shut-off solenoid engage with a click.

C - START Position - Move key from ON to this position and the starter will engage the engine flywheel to start the engine. Release the key to the ON position.

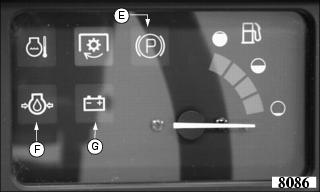

Understanding Instrument Panel - Right Side

A - Engine Coolant Temperature Light - This light will turn on when the engine coolant is approaching a dangerously hot temperature. If this light turns on during operation, remove load on tractor immediately. Reduce engine to idle speed and check for something blocking air flow to the radiator and check engine coolant level. If light stays on after cleaning grille, stop engine.

B - PTO Engagement Light - This light will turn on when the PTO is engaged.

C - Park Brake Light - This light will turn on and flash when the park brake is locked.

D - Engine Oil Pressure Light - This light will turn on when the ignition key is in the ON position and the engine is not running. If this light turns on while the engine is running, engine oil pressure is too low. Stop engine.

E - Alternator/Battery Charging Light - This light will turn on when the ignition key is in the ON position and the engine is not running. If this light turns on while the engine is running, the alternator output is too low. Move the throttle lever to the full throttle position. Stop the engine if light remains on.

F - Fuel Gauge - Show approximately how much fuel is in the fuel tank.

Understanding Instrument Panel - Left Side

A - Tachometer - Shows engine speed. Engine speed is shown in 100's. Example: If indicator is pointing at 20 (20 x 100 = 2000 RPM). Note the special marker labeled "540." With the indicator pointing at the "540" marker, this is the proper engine speed for the 540 RPM Power Take Off (PTO).

· Slow idle speed..................1025 rpm

· Rated speed....................... 2650 rpm

· Fast speed.......................... 2860 rpm

B - Warning Flasher/Turn Signal Indicator Light - This light will turn on and flash when the light switch is turned to the Warning Flasher Lights ON position or Headlights, Taillights and Warning Flasher Lights ON position.

C - Hour Meter - Shows total number of accumulated running hours. Use the hour meter as a guide when servicing various components of this tractor.

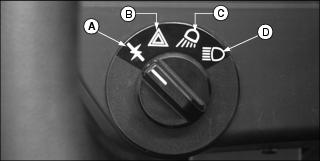

Using Light Switch

NOTE: The light switch will operate only when the ignition key switch is in the ON position.

C - Headlights and Taillight On

D - Headlights, Taillight, Flasher Lights On

Using Throttle

Picture Note: Gear model shown in photo.

Use the throttle to change engine speeds. Use the throttle in conjunction with the tachometer to set engine speeds.

Hand Throttle (All Models)

Foot Throttle (Gear Models Only)

NOTE: The foot throttle can be used in conjunction with the hand throttle. Example: Use the hand throttle to set engine speed at 2000 RPM. Push down the foot throttle pedal to increase engine speed to 2860 RPM. Release foot throttle and engine speed will return to the hand throttle setting of 2000 RPM.

Engine/Tachometer Speeds:

· Slow Idle Speed................................................1025 rpm

· Special Marker "540"........................................2650 rpm

· Rated Speed.....................................................2650 rpm

· Fast Speed.......................................................2860 rpm

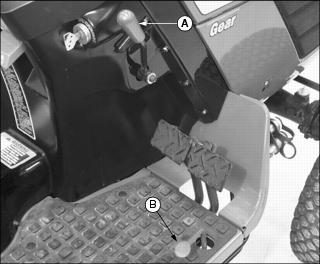

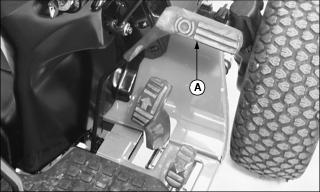

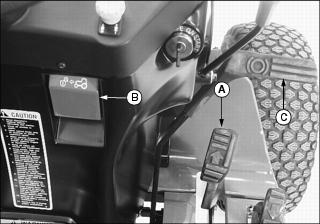

Using Brake Pedals (Gear Models)

Using Brake Pedal As Driving Brake

· Lock pedals together when not using the turn brakes or for road travel. |

NOTE: Right brake pedal must be depressed slightly to install brake pedal lock latch.

1. Rotate brake pedal latch (A) down to lock into right turn brake pedal (B).

2. Depress either foot pedal to slow or stop the machine.

· With latch down, brakes should stop tractor in a straight line.

Using Brake Pedals To Assist In Turning

IMPORTANT: Avoid damage! Do not apply turn brakes while an attachment is engaged with the ground. Damage to the 3-point hitch and attachment may occur. |

NOTE: Unlocked brake pedals can be used to make tighter turns and may prevent unnecessary backing. Lock brake pedals together when driving the machine to another work site or when driving on a roadway.

1. Rotate brake pedal latch (A) up until it stops against left turn brake pedal (C). The brake pedals will now function independently.

· To make a tighter left turn, depress left turn brake pedal (C) while turning to the left.

· To make a tighter right turn, depress right turn brake pedal (B) while turning to the right.

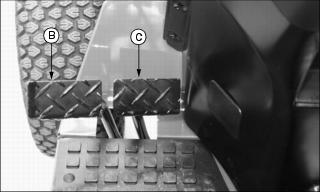

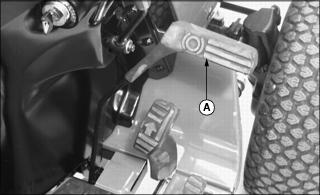

Using Brake Pedals (Hydrostatic Models)

Using the Master Brake Pedal

· Depress the master brake pedal (A) to stop the tractor.

· Depress the master brake to cancel the preset speed of the cruise control if the cruise control is activated.

Using Turn Brake Pedals

IMPORTANT: Avoid damage! Do not apply turn brakes while an attachment is engaged with the ground. Damage to the 3-point hitch and attachment may occur. |

NOTE: Turn brake pedals can be used for tighter turns. Using turn brake pedals may also prevent unnecessary backing.

· To make a tighter left turn, depress left turn brake pedal (B) while turning to the left.

· To make a tighter right turn, depress right turn brake pedal (C) while turning to the right.

Using Park Brake (Gear Models)

Locking Park Brake

NOTE: Right brake pedal must be depressed slightly to install brake pedal lock latch.

1. Lock both brake pedals together using brake pedal lock latch (A).

2. Press down completely on both brake pedals with foot.

3. Lift park brake lock (B) completely up to the locked position.

4. Remove foot from brake pedals. Both pedals should now stay down in the locked position.

Unlocking Park Brake

1. Press down completely on brake pedals with foot.

2. Push park brake lock (B) completely down to the unlocked position.

3. Remove foot from brake pedals. Both pedals should now be released from the locked position.

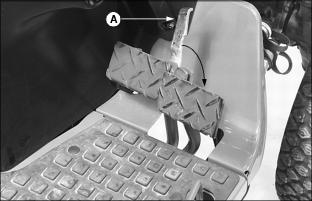

Using Park Brake (Hydrostatic Models)

Locking Park Brake

1. Depress master brake pedal (A) with foot.

2. Lift park brake lock (B) completely up to the locked position.

3. Remove foot from brake pedal. Brake pedal should now stay down in the locked position.

Unlocking Park Brake

1. Depress master brake pedal (A) with foot.

2. Push park brake lock (B) completely down to the unlocked position.

3. Remove foot from brake pedal. Brake pedal should now be released from the locked position.

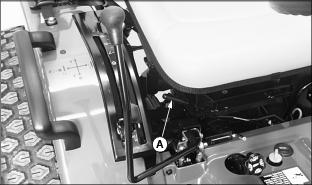

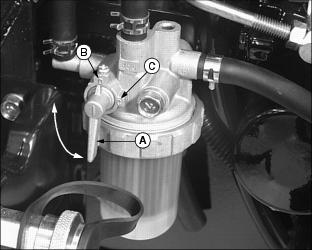

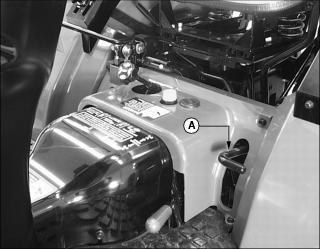

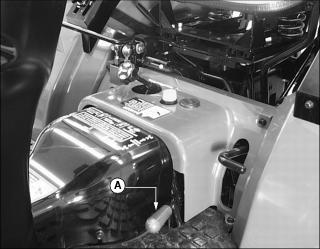

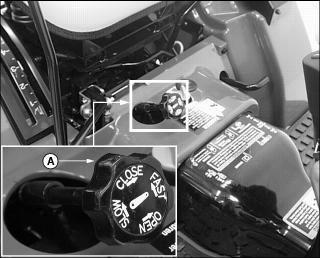

Using Fuel Shut-Off Valve

Close the valve when performing any type of engine service, during transport of the machine, and during storage.

1. Raise and latch hood in the open position.

2. Remove side panel from right side of engine.

3. Open or close fuel shut-off valve lever (A) as required:

Starting the Engine

1. Open the fuel shut-off valve.

3. Gear Models: Move the 2-speed range and direction lever (A) to the N position.

4. Gear Models: Move the PTO lever (B) to the disengaged/off position.

5. Hydrostatic Models: Move the 2-speed range lever (A) to the N position.

6. Hydrostatic Models: Push PTO control knob (B) down to the disengaged/off position.

NOTE: To prevent sudden lift, lower all attachments to the ground before starting the tractor.

7. Lower any rear mount or midmount attachment to the ground by pushing rockshaft control lever forward.

8. Lower any front mounted attachment(s) to the ground using optional SCV lever.

9. Set hand throttle lever (D) to the 1/2-3/4 fast position.

10. Turn ignition key switch to the ON position.

· Park brake light (E) will glow and flash if park brake is locked.

· Engine oil pressure light (F) will glow.

· Alternator/battery charging light (G) will glow.

NOTE: Glow plugs preheat the engine for better starting performance.

12. Allow the glow plugs to preheat the engine. After approximately three seconds listen for a click. Engine is now ready to start.

13. Gear Models: Depress the clutch pedal completely.

14. Turn key switch to START position. Release key when engine starts.

15. Gear Models: Remove foot from clutch pedal.

· Engine oil pressure light should go out within 5 seconds.

NOTE: Set engine speed at full throttle if indicator light does not go out after 10 seconds.

· Alternator/battery charging light should go out within 10 seconds.

· If indicator lights stay on longer than the given time interval, stop engine and check for cause.

IMPORTANT: Avoid damage! In cold weather, idle engine several minutes to allow engine oil and transmission oil to warm. |

NOTE: Allowing engine to idle for long periods of time will waste fuel and cause carbon build-up.

It is normal for the engine to be louder and for blue-white exhaust smoke to be present during engine warm-up. The amount of exhaust smoke depends on air temperature.

17. Set hand throttle lever to the 1/2 fast position for 1 minute without load.

Cold Weather Starting Aids

· Install optional engine coolant heater if you operate tractor in temperatures below -18° C (0° F).

· Install optional transmission oil heater if you operate tractor in temperatures below -18° C (0° F).

Warming and Idling the Engine

IMPORTANT: Avoid damage! In cold weather, idle engine several minutes to allow engine oil and transmission oil to warm. |

NOTE: Allowing engine to idle for long periods of time will waste fuel and cause carbon build-up.

It is normal for the engine to be louder and for blue-white exhaust smoke to be present during engine warm-up. The amount of exhaust smoke depends on air temperature.

1. Gear Models: Lock brake pedals together using brake pedal lock latch.

Warming Engine

· Set hand throttle lever to the 1/2 fast position for 5 minutes without load.

Idling Engine

· Adjust hand throttle lever rearward to set engine speed at 1025 rpm (slow idle speed).

Starting a Stalled Engine

IMPORTANT: Avoid damage! If engine stalls while operating under load, start engine immediately to prevent abnormal heat build-up in engine. |

Gear Models

2. Move the 2-speed range and direction lever to the N position.

3. Move the PTO control lever to the disengaged/off position.

4. Start engine. Continue with normal operation, or set engine speed at slow idle speed for 1 or 2 minutes before stopping.

Hydrostatic Models

1. Move the 2-speed range lever to the N position.

2. Push PTO knob down to the disengaged/off position.

3. Start engine. Continue with normal operation, or set engine speed at slow idle speed for 1 or 2 minutes before stopping.

Stopping Tractor

Normal Stopping

1. Gear Models: Depress clutch pedal all the way down and stop tractor with both brake pedals.

2. Hydro Models: Depress master brake pedal.

4. Gear Models: Move the 2-speed range and direction lever to the N position.

5. Hydro Models: Move the 2-speed range lever to the N position.

6. Push rockshaft control lever forward to lower any attachment to the ground.

7. If tractor is equipped with optional SCV, lower any attachments to the ground using the SCV lever.

8. Gear Models: Lock brake pedals together using brake pedal lock latch.

10. Adjust hand throttle rearward to set engine speed at 1025 rpm (slow idle speed). Allow engine to idle for 2 minutes.

11. Turn key switch to OFF position.

13. Wait for the engine and all moving parts to stop before leaving the operator's station.

Emergency Stopping (Gear Models)

1. Depress clutch pedal all the way down and depress both brake pedals.

2. Turn key switch to OFF position. Do not release clutch pedal until all moving parts have stopped.

3. If possible, lock the park brake.

Emergency Stopping (Hydrostatic Models)

1. Depress master brake pedal.

2. Turn key switch to OFF position. Do not release master brake pedal until all moving parts have stopped.

3. If possible, lock the park brake.

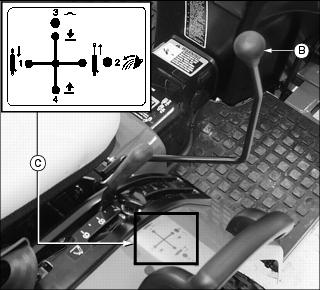

Selecting a Range or Gear (Gear Transmission)

The gear shift lever provides four gear positions. Gears may be changed while tractor is in motion if clutch pedal is depressed.

The 2-speed range and direction lever provides two speed ranges with reverse. Tractor motion must stop and the clutch must be depressed before changing speed ranges.

Use both the transmission gear and range shift levers in different combinations to achieve eight forward and four reverse speeds.

Choose a speed range to match work application:

Choose a gear that matches the immediate power/speed requirements:

· 1st Gear - High power, low speed operations.

· 2nd Gear - Medium power, moderate speed operations.

· 3rd Gear - Low power, moderate speed operations.

· 4th Gear - Low power, high speed operations.

Driving Tractor (Gear Model)

2. Depress clutch pedal completely.

3. Move the transmission range shift lever to the L (low), H (high) or R (reverse) position.

4. Move transmission gear shift lever to selected gear position.

6. Release clutch pedal gradually to take up load smoothly.

7. Adjust throttle speed to match expected load.

· To maintain a constant operating speed, adjust the engine speed with the hand throttle.

· To repeatedly increase and decrease engine speed, leave the hand throttle set at the middle position and use the foot throttle to increase the engine speed.

8. Depress clutch and shift gears to increase speed.

9. Stop tractor motion to change speed range.

Selecting a Range (Hydrostatic Transmission)

The range shift lever provides two speed ranges.

Choose speed range with range shift lever to match work application:

Driving Tractor (Hydrostatic Model)

IMPORTANT: Avoid damage! To prevent transmission damage, stop tractor motion before shifting the range shift lever. |

2. Move the 2-speed range lever to the L (low) or H (high) position.

3. Depress master brake pedal.

5. Release master brake pedal.

NOTE: When the travel pedal is released, the transmission will automatically return to neutral.

6. Slowly depress pedal downward to travel forward. Slowly depress pedal downward to travel in reverse.

· The farther either pedal is depressed, the faster the tractor will travel.

7. Stop tractor motion to change speed range.

Using the Cruise Control (Hydrostatic Models Only)

Engaging Cruise Control

NOTE: The cruise control is only operational when the tractor is traveling forward.

1. Depress forward travel pedal (A) until a desirable operating speed is reached.

2. Raise lever (B) to engage the cruise control.

3. Release forward travel pedal.

Disengaging Cruise Control

1. Depress forward travel pedal (A) or master brake pedal (C).

Using Differential Lock

To prevent tipping, do not engage differential lock with following conditions: |

The differential lock is used to provide better traction when rear wheels start to slip. Engaging differential lock will lock right and left side rear axles together and cause both rear wheels to turn at equal speeds for maximum traction.

NOTE: Turning radius is increased when differential lock is engaged. To assist turning, release differential lock and use turn brake pedals.

Engaging Differential Lock

1. Stop or slow tractor movement.

NOTE: Differential lock will remain engaged as long as rear wheel slippage occurs. If tires slip and regain traction repeatedly, hold down pedal with foot so differential lock remains engaged.

Picture Note: HST model shown. Lever is on the opposite side for gear tractors.

2. Push down on differential lock pedal (A) to engage differential lock.

Disengaging Differential Lock

1. Remove foot from differential lock pedal.

NOTE: Rear wheel slippage will keep differential lock engaged. Lock will automatically disengage when traction equalizes.

2. If lock does not disengage when removing foot from pedal, depress one turn brake pedal and then the other.

Using Mechanical Front Wheel Drive (MFWD)

Mechanical front wheel drive (MFWD) enables the powertrain to drive all four wheels for improved traction on difficult ground conditions and provides 4-wheel braking. MFWD can be engaged and disengaged on-the-go with light loads and on low-tractive surfaces.

Picture Note: HST model shown.

NOTE: It may be necessary to reduce engine load to disengage front wheel drive.

Pull up on MFWD lever (A) to engage front wheel drive system. Push down on lever to disengage the system.

Tips for operating MFWD

· Maintain front tire pressure at maximum allowable level to ensure proper tire performance in all field conditions.

· Engage MFWD to provide four-wheel braking.

· Disengage MFWD when driving tractor to or from work site to increase front tire life.

· MFWD may be engaged and disengaged on-the-go with light loads and on low-tractive surfaces.

Using the Power-Take-Off (PTO) Safely

Using the Rear and Mid Power-Take-Off (PTO) (Gear Models) (Operator On Seat)

NOTE: The model 4100 Narrow tractor is not equipped with a mid PTO. A mid-PTO or loader should never be installed on a Narrow model tractor.

Engaging the PTO

3. Depress clutch pedal completely.

4. Move the transmission gear shift lever to the neutral position.

5. Move the 2-speed range and direction lever to the N position.

NOTE: The starter will not crank if the PTO control lever is in any engaged/on position.

If the operator leaves the seat with the engine running and the PTO engaged, the safety interlock system will stop the engine and all attachments.

7. Move the PTO control lever (A) to a desirable engaged/on position.

· Position (B) - Mid PTO only.

· Position (C) - Mid and Rear PTO

· Position (D) - Rear PTO only.

· The instrument panel PTO engaged light will illuminate when the PTO is engaged.

8. Adjust hand throttle lever forward until tachometer indicator points to the special 540 rpm marker.

· Tachometer should indicate engine speed to be 2650 rpm.

· Rear PTO speed will be 540 rpm.

· Mid PTO speed will be 2117 rpm.

Disengaging the PTO

1. Adjust engine rpm to low idle.

2. Move the PTO control lever to the disengaged/off position.

· The instrument panel PTO engaged light will go out when the PTO is disengaged.

Using the Rear and Mid Power-Take-Off (PTO) (Hydrostatic Models) (Operator On Seat)

Engaging the PTO

3. Move the 2-speed range lever to the N position.

NOTE: The starter will not crank if the PTO control knob is in any engaged/on position.

If the operator leaves the seat with the engine running and the PTO engaged, the safety interlock system will stop the engine and all attachments.

5. Move the PTO control lever (A) to a desirable operating position.

· Position (B) - Mid PTO only.

· Position (C) - Mid and Rear PTO

· Position (D) - Rear PTO only.

6. Pull PTO control knob up to the engaged/on position.

· The instrument panel PTO engaged light will illuminate when the PTO is engaged.

7. Adjust hand throttle lever forward until tachometer indicator points to the special 540 rpm marker.

· Tachometer should indicate engine speed to be 2650 rpm.

· Rear PTO speed will be 540 rpm.

· Mid PTO speed will be 2117 rpm.

Disengaging the PTO

1. Adjust engine rpm to low idle.

2. Push PTO knob down to the disengaged/off position.

· The instrument panel PTO engaged light will go out when the PTO is disengaged.

Using the Rear Power-Take-Off (PTO) (Operator Off Seat)

NOTE: Only the rear PTO can be engaged with the operator off the seat. The Safety Interlock System will stop the engine and all attachments if the mid-PTO is engaged.

3. Gear Models: Move the transmission gear shift lever to the neutral position.

4. Move the transmission range shift lever to the N (neutral) position.

7. Raise operator seat to locate the seat switch stop and two position seat switch.

NOTE: With the seat switch stop in the raised position the operator seat can be lowered without deactivating the seat switch.

9. Raise seat switch stop (B).

NOTE: Depress clutch pedal when engaging and disengaging the PTO control lever.

11. Gear Models: Depress clutch pedal completely.

Engaging Rear PTO

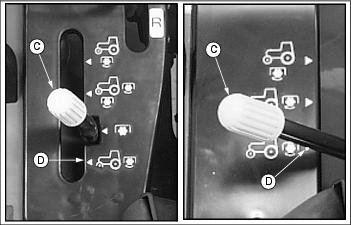

Picture Note: Gear model shown in left photo. Hydrostatic model shown in right photo.

1. Move the PTO control lever (C) to the rear PTO engaged/on position (D).

2. Hydrostatic Models: Pull PTO control knob up to the engaged/on position.

3. Look: The instrument panel PTO engaged light will illuminate when the PTO is engaged.

4. Adjust hand throttle lever forward until tachometer indicator points to the special 540 rpm marker.

· Tachometer should indicate engine speed to be 2650 rpm.

· Rear PTO speed will be 540 rpm.

Disengaging Rear PTO

1. Gear Models: Move the PTO control lever to the disengaged/off position.

2. Push PTO knob down to the disengaged/off position.

3. Look: The instrument panel PTO engaged light will go out when the PTO is disengaged.

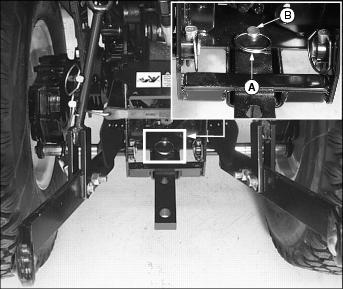

Using Drawbar Hitch

Maximum Drawbar Loads

Certain heavy equipment such as a loaded single-axle trailer can place excessive strain on the drawbar. Strain is greatly increased by speed and rough ground. Do not exceed the following maximum static vertical loads on drawbar:

· All Models...............................................259 kg (570 lb)

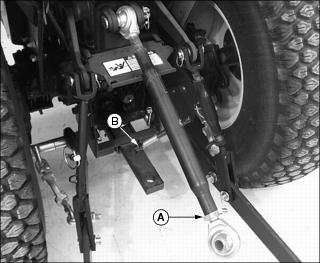

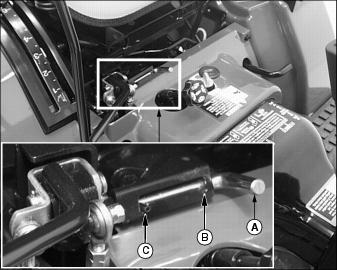

Adjusting Drawbar Length

The drawbar is equipped with three adjusting holes for changing drawbar length.

1. Remove locking ring (A) and pin (B).

2. Adjust drawbar (C) to desired length.

3. Install pin up from bottom of tractor. Secure with locking ring.

Using 3-Point Hitch

1. Slowly back tractor into position to align draft links with attachment lift brackets.

2. Park machine safely. (See Parking Safely in the SAFETY section.)

3. Connect draft links (A) to the attachment.

NOTE: When the 3-point hitch is not being used, return center link to storage hook.

4. Remove center link (B) from storage hook (C).

5. Attach center link to the attachment top mast. Adjust center link and lift links as necessary.

6. Level the attachment side to side and front to rear.

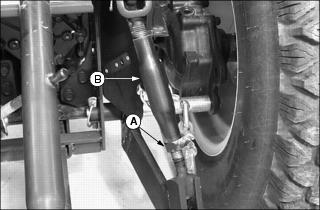

Leveling Attachment Front-to-Rear

1. Lower any rear mount attachment to the ground.

2. Park machine safely. (See Parking Safely in the Safety section.)

4. Rotate handle (B) to lengthen or shorten the center link.

Leveling Attachment Side-to-Side

1. Lower any rear mount attachment to the ground.

2. Park machine safely. (See Parking Safely in the Safety section.)

4. Rotate lift link body (B) to raise or lower draft link until 3-point hitch mounted attachment is level from side-to-side.

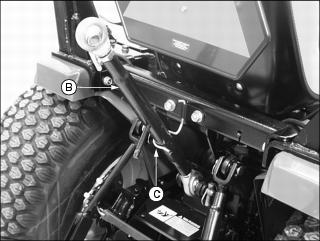

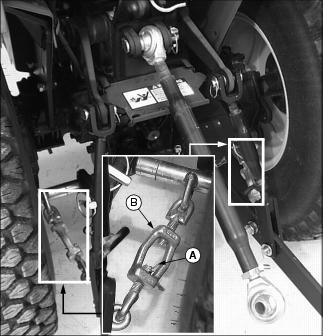

Adjusting Attachment Side-to-Side Sway

NOTE: Check attachment operator's manual procedure for adjusting sway links. When sway links have been properly adjusted, side sway of attachment is controlled by position of links.

1. Lower any rear mount attachment to the ground.

2. Park machine safely. (See Parking Safely in the SAFETY section.)

3. Remove spring locking pin (A).

4. Rotate turnbuckle (B) to adjust length.

5. Install spring locking pin.

Using Speed of Drop/Lock Valve

The speed of drop/lock valve controls the rate of rockshaft drop when the rockshaft control lever is operated. This provides direct rate of drop control for 3-point hitch mounted attachments. The valve can also be use to hydraulically lock the rockshaft (three-point hitch) in a desired position.

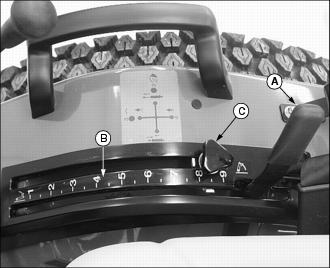

Using the Rockshaft Control Lever

Use rockshaft control lever (A) to raise and lower equipment attached to the 3-point hitch.

Rockshaft control lever label (B) shows nine calibrated settings. These calibrations are for reference only and do not signify specific operating depths. When the rockshaft control lever is moved forward, the draft arms will lower closer to the ground.

The adjustable depth stop (C) can be adjusted to maintain a particular attachment operating depth. To use the depth stop knob:

1. Operate attachment for a few minutes to determine the desired operating depth.

2. Loosen the depth stop knob.

3. Move knob against rockshaft control lever.

4. Tighten knob to keep the depth stop in position. Attachment will operate in same position each time rockshaft control lever is pushed against the depth stop.

Using Optional Hydraulic Selective Control Valve (SCV)

This tractor model series can be equipped with an optional hydraulic Selective Control Valve (SCV) and hydraulic outlets to operate hydraulically-driven attachments.

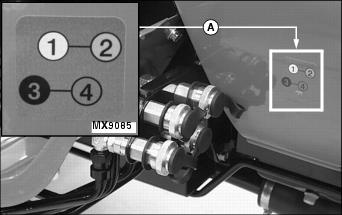

The tractor-mounted hydraulic outlets are female quick couplers numbered and color coded easy hookup. Decal (A) identifies the couplers: 1 (yellow), 2 (red), 3 (black), and 4 (green).

Attachment hydraulic hoses are also color coded. Match the color coded hose ends to the color coded hydraulic couplers on tractor when making connections.

When the attachment hydraulic hoses are connected to couplers 1 (yellow) and 2 (red), move SCV lever (B) left to raise attachment, or right to lower attachment.

When the attachment hydraulic hoses are connected to couplers 3 (black) and 4 (green), move SCV lever (B) forward to dump attachment, or rearward to retract attachment.

Refer to information label (C) if further operating assistance is required.

The SCV is equipped with a float position in order to permit attachments such as blades or loaders to follow ground contours when lowered to operating position. Push SCV lever forward past valve detent to attain float position.

IMPORTANT: Avoid damage! To prevent contamination of female quick couplers, plastic caps should be installed in the couplers when not being used. |

Using Selective Control Valve (SCV) Lock Lever

Picture Note: SCV lock lever shown in the locked position.

· Move lock lever (A) to position (B) to allow SCV lever movement in all directions. Operation of the SCV is unlocked.

· Move lock lever (A) to position (C) to prohibit SCV lever movement in all directions. Operation of the SCV is locked.

Connecting Attachment Hydraulic Hoses

1. Park machine safely. (See Parking Safely in the SAFETY section.)

2. Relieve all hydraulic pressure by moving SCV lever rearward-to-forward and side-to-side several times.

3. Refer to attachment operator's manual for instructions on connecting hydraulic hoses to couplers.

Transporting Tractor

Driving Tractor Safely on Roads

Observe the following precautions when operating the tractor on a road:

· Gear Models: Make sure brake pedals are evenly adjusted and locked together with the brake pedal latch.

· Make sure Slow Moving Vehicle (SMV) emblem and warning lights are clean and visible. If towed or rear-mounted equipment obstructs these safety devices, install SMV emblem and warning lights on equipment.

· Turn on flashing warning lights and headlights on, except if prohibited by law.

· Tractors with cabs must have at least one rear view mirror to permit the operator to see the road behind the machine.

· Secure towed loads with locked hitch pins and safety chains.

· Drive slowly enough to maintain safe control at all times. Slow down for hillsides, rough ground, and sharp turns, especially when transporting heavy, rear-mounted attachments.

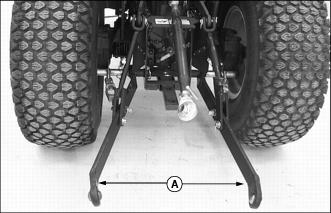

· Adjust tread width position of rear wheels to provide maximum stability.

· If equipped, disengage the MFWD to reduce tire wear.

· Never coast tractor downhill.

Pushing or Towing Tractor

1. Pull PTO control lever rearward to the disengaged/off position.

2. Disengage differential lock.

4. Gear Models: Place transmission in the neutral position.

5. Place the range shift lever in the N (neutral) position.

7. Gear Models: Connect both turn brake pedals as a driving brake to slow or stop tractor.

Transporting Tractor on a Trailer

NOTE: Use a heavy-duty trailer to transport machine.

1. Drive machine forward onto trailer.

2. Lower any attachments to trailer deck.

6. Close the fuel shut-off valve.

7. Fasten machine to trailer with heavy-duty straps, chains, or cables. Both front and rear straps must be directed down and outward from machine. Trailer must have signs and lights as required by law.

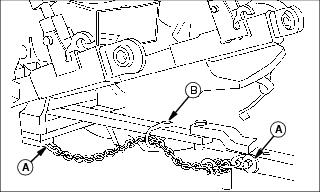

Using Safety Chain

1. Use the appropriate adapter parts (A) to attach the safety chain to the tractor drawbar support and to the towed load. Provide only enough slack to permit turning.

2. Install additional attaching points (B) for the chain on drawbar to reduce slack in chain when necessary.

3. Remove the safety chain and store when not in use.

Towing Loads

1. Hitch the towed load only to the drawbar. Lock the drawbar and pin in place.

2. Install a safety chain to the tractor drawbar support and to the towed load. Provide only enough slack to permit turning.

3. Gear Models: Before descending a hill, shift to a gear low enough to control tractor travel speed without having to use the brake pedals to brake the tractor and installed attachments.

Determining Maximum Rear Ballast

Locate the maximum load information embossed into the tire side wall.

Use the following charts to determine the maximum inflation pressures to use with tires at maximum loads.

Remove ballast when no longer needed.

Using Optional Rear Cast Iron Wheel Weights

NOTE: Rear wheels installed on model 4100 Narrow tractors are one position wheels.

1. Mount rear wheels in the narrow position for improved stability.

2. Fasten weight to each rear wheel using a safe lifting device. A total of three weights per wheel may be used. See your attachment operator's manual for installation and number of weights to use.

Rear wheel weights are available from your John Deere Dealer.

Using Optional Rear Ballast Box

The rear ballast box is used for carrying ballast on the 3-point hitch. Approximate weight of different materials is given in the attachment operator's manual.

Using Liquid Weight in Tires

NOTE: Use of alcohol as ballast is not recommended. Calcium chloride solution is heavier and more economical.

A solution of water and calcium chloride provides safe economical ballast, and will prevent freezing. If used properly, it will not damage tires, tubes, or rims.

A mixture of 0.4 kg of calcium chloride per liter of water (3.5 lb/gal), will not freeze solid above -45° C (-50° F).

Fill tubeless tires at least to valve stem level (minimum 75% full). Less solution would expose part of rim, possibly causing corrosion.

Tube-type tires may be filled to any level below 90%.

Determining Maximum Front Ballast

Add weight to front end if needed for stability. Heavy pulling and heavy rear mounted implements tend to lift front wheels. Add enough ballast to maintain steering control and prevent tip over. Remove weight when it is no longer needed.

Use the following chart to determine the maximum inflation pressures to use with tires at maximums loads.

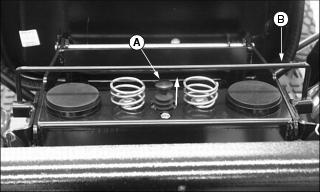

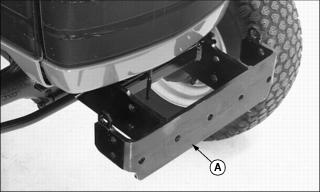

Using Optional Front Weights

Front weight bracket (A) is an integral part of the tractor frame. The bracket will hold up to five Quick-Tatch® weights.

Quick-Tatch weights and attaching hardware are available at your John Deere dealer.

See your attachment operator's manual for installation and required number of weights to use.

Optional Front Weight Bracket Extension

There is an optional front weight bracket extension kit available at your John Deere dealer. This optional front weight bracket extension kit will hold up to nine Quick-Tatch weights.