PIN TC1420G010001, TC1435D010001, TC1445D010001

Introduction

Product Identification

Safety

Operating Machine

Avoid Damage to Plastic and Painted Surfaces

Testing Seat and Park Brake Switch

Using Four Wheel Drive (4WD) (Optional)

Using Fuel Shutoff Valve (Diesel Models Only)

Raising and Lowering the Attachment

Moving Machine with Engine Off

Transporting Machine on Trailer

Replacement Parts

Service Intervals

Service Lubrication

Service Engine

Service Transmission

Service Steering & Brakes

Service Electrical

Service Miscellaneous

Troubleshooting

Storage

Assembly

Specifications

Warranty

John Deere Quality Statement

Service Record

CopyrightŠ Deere & Company

Operating Machine

Daily Operating Checklist

o Check engine, transaxle, and 4WD oil levels.

o Remove debris from machine and attachment.

o Check area below machine for leaks.

o Check air restriction indicator.

o Remove debris from radiator, oil cooler, and alternator.

o Check brakes and forward and reverse pedals.

Avoid Damage to Plastic and Painted Surfaces

ˇ Do not wipe plastic parts unless rinsed first. Using a dry cloth may cause scratches.

ˇ Insect repellent spray may damage plastic and painted surfaces. Do not spray insect repellent near machine.

ˇ Be careful not to spill fuel on machine. Fuel may damage surface. Wipe up spilled fuel immediately.

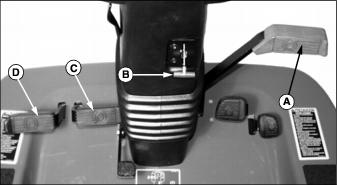

Operator Station Controls

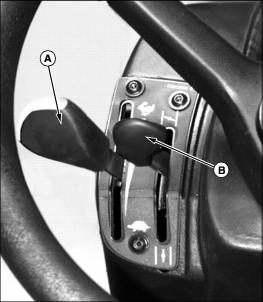

B - Choke Lever (Model 1420 Only)

B - Engine Manifold Heater Lamp (1435, 1445 Only)

C - Engine Coolant Temperature Lamp

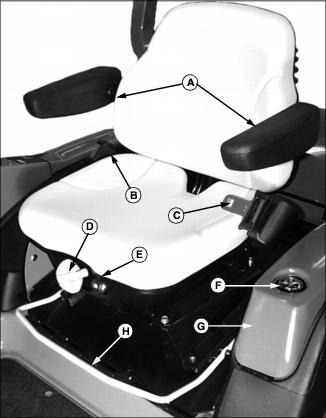

A - Steering Column Tilt Lock Lever

D - Seat Spring Adjustment Knob

E - Seat Spring Weight Indicator

A - Seat Height Adjustment Lever

Miscellaneous Controls

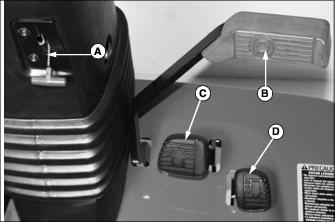

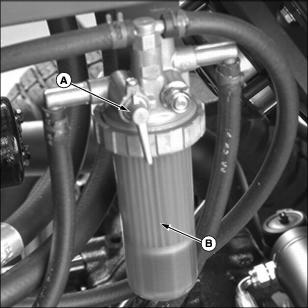

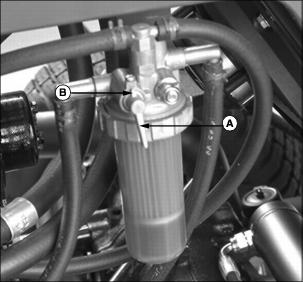

A - Fuel Shutoff Valve (Diesel Models)

B - Fuel Filter/Water Separator (Diesel Models)

Testing Safety Systems

Use the following checkout procedure to check for normal operation of machine.

If there is a malfunction during one of these procedures, Do not operate machine. See your John Deere dealer for service.

Perform these tests in a clear open area. Keep bystanders away.

Testing PTO Switch

1. Sit on the seat. (Seat should spring down slightly so seat switch is actuated.)

3. Pull PTO switch up to the on position.

5. Unlock the park brake (keep the PTO switch on). Try and start the engine.

Testing Seat and Park Brake Switch

1. Sit on seat. (Seat should spring down slightly so seat switch is actuated.)

2. Push PTO switch down to the off position.

3. Push down master brake pedal.

5. Release master brake pedal.

6. Raise up off of seat, but do not get off tractor.

Testing the Park Brake

1. Stop machine on a 17° slope (30% grade). Stop the engine and lock the park brake.

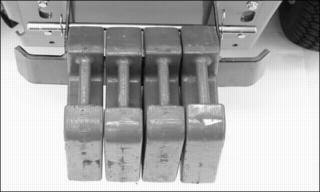

Using Proper Ballast

ˇ Attachments used with this machine may require ballast to prevent tipping and loss of control when the attachment is raised.

ˇ Check the attachment operator's manual or see your John Deere dealer for ballasting information.

Adjusting Seat

To adjust seat position:

2. Pull seat adjustment lever (A) up, out of locked position.

3. Slide seat forward or rearward to desired position.

To adjust seat spring tension:

1. Turn seat spring adjustment knob (B) adjust seat spring tension while watching weight indicator (C).

2. Match weight of operator to value shown in weight indicator. Seat must spring slightly so that operator's presence switch will be actuated, allowing engine to start.

To adjust seat height:

1. Pull up on the front of the base of the seat, and the seat height adjustment lever (A), until the seat height lock disengages.

2. Raise or lower the operator's seat to desired height. (There are four positions available.)

3. Release the seat height lock lever and continue to move the seat slightly until it latches in place.

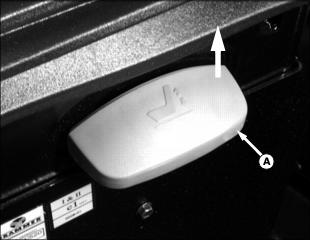

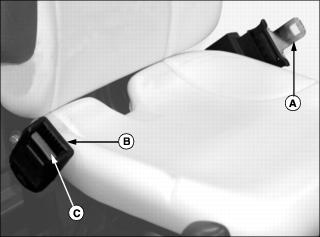

Using Seat Belt

2. Pull out seat belt buckle (A) and stretch across your lap in one non-stop motion.

3. Insert seat belt buckle into latch (B) until it locks.

4. To release seat belt, press red button (C) until buckle comes out of latch.

Adjusting Steering Column

2. Pull lever (A) outward to release steering column.

3. Push steering wheel forward or rearward to desired position.

4. Push lever back in to lock steering column in place.

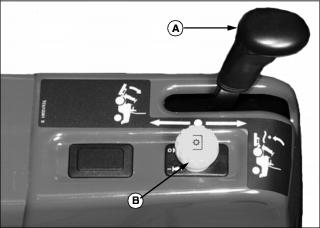

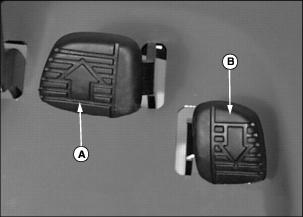

Using PTO Switch

NOTE: Starter will not crank if PTO is engaged.

PTO will disengage if engine overheats.

PTO will disengage if master brake pedal is depressed.

ˇ To turn PTO off, push PTO knob (A) down.

ˇ To turn PTO on, pull PTO knob up.

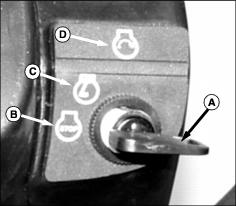

Using Key Switch

NOTE: Starting motor will engage only if the following conditions exist:

ˇ Master brake pedal is depressed.

ˇ To turn ignition off, turn the key (A) to the stop position (B).

ˇ To turn ignition on, turn key to the run position (C). Some indicator lights on instrument panel will light, and beeper will sound.

ˇ To start engine, turn key to the start position (D). All indicator lights will light. Once engine begins to run, release key switch back to the run position (C).

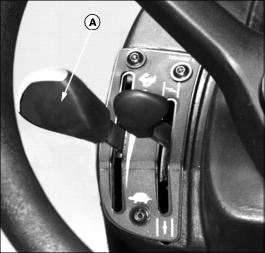

Using Throttle Lever

ˇ Pull the throttle lever (A) to the rear for slow idle. Use this position to start engine and maneuver the mower in confined spaces.

ˇ Push throttle lever fully forward to the fast idle position for transporting and mowing.

Using Choke Lever (1420 Only)

ˇ Push the choke lever (A) forward to aid in starting the engine when cold.

ˇ Pull the choke lever rearward once engine has started, or when restarting the engine when hot.

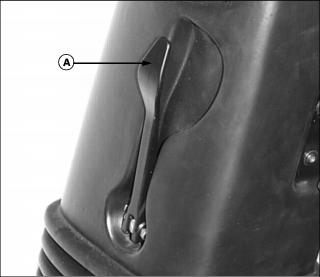

Opening Engine Cover

1. Park machine safely. (See Parking Safely in the Safety section).

2. Press the engine cover latch (A) fully down.

3. Pull the engine cover handle (B) rearward until it stops.

4. To close engine cover, push forward on handle until engine cover latch pops up into latched position.

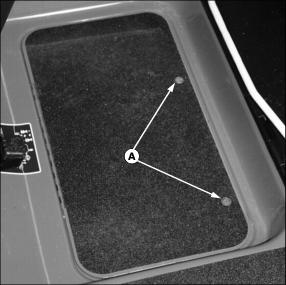

Opening Service Hatch

1. Park machine safely. (See Parking Safely in the Safety section.)

2. Unlock service hatch locks (A) by turning each one 3\4 turn counter clockwise with a large screwdriver.

3. Lift rear edge of service hatch to open.

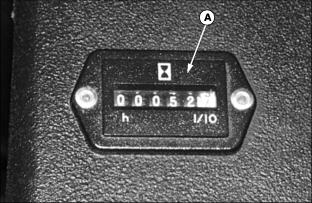

Hour Meter

The hour meter (A) records the number of hours the engine has run. It is located inside the engine compartment on the back of the right hand side console. Electronic hour meters can be read with key switch in on position.

Use the hour meter and the service interval chart to determine when service procedures need to be performed on the machine and mower deck.

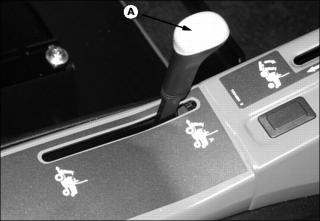

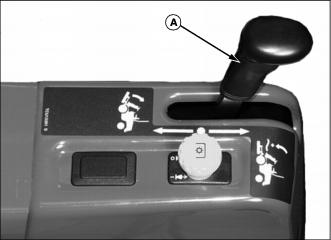

Using Four Wheel Drive (4WD) (Optional)

ˇ Push 4WD lever (A) forward (position shown) to use on-demand four wheel drive. Rear wheels will engage whenever front wheel slip is detected, and will disengage automatically.

ˇ Pull 4WD lever rearward to engage full time four wheel drive. Four wheel drive is locked in for forward and reverse travel.

ˇ Traveling forward (slowly) while pulling the 4WD lever rearward helps to engage the 4WD lock.

ˇ Traveling rearward (slowly) while pushing the 4WD lever forward helps to disengage the 4WD lock.

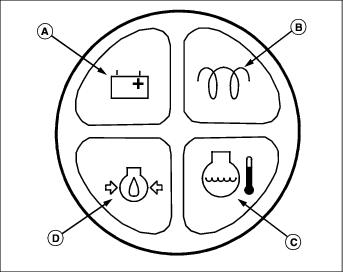

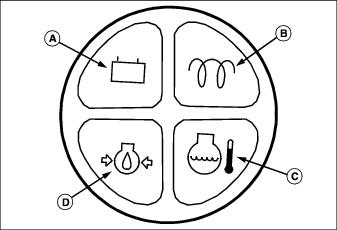

Indicator Lamps

IMPORTANT: Avoid damage! If an indicator lamp turns on while the engine is running, stop the engine to avoid engine damage. Before you restart the engine, find and correct the cause. |

ˇ The battery discharge light (A) indicates the battery is not getting enough charge from the alternator. The light should come on when the key switch is turned to the run position, and should go off once the engine starts.

Engine Manifold Heater Indicator Lamp (Diesel Only)

ˇ The manifold heater light (B) will light to indicate the intake manifold heater is energized and the operator should wait until it goes off before starting the engine.

ˇ The manifold heater is controlled by a temperature sensitive timer, and will turn off sooner in warm weather.

ˇ Starting the engine before indicator turns off will waste fuel, create smoke, and put unnecessary wear on starter.

Engine Coolant Temperature Lamp

ˇ The engine coolant temperature light (C) indicates that the engine is overheating. The warning beeper will sound when the lamp turns on, and the PTO will disengage.

ˇ If the lamp lights while mowing, perform the following steps:

a. Remove foot from hydrostatic pedal to stop travel.

b. Push PTO switch down to off position.

e. If a major coolant leak is seen coming from the engine compartment, stop the engine immediately.

f. If no coolant or steam can be seen leaking from the engine, open the engine cover and verify that the engine cooling fan is running. If it is, allow engine to idle for five minutes, or until coolant temperature light goes off, then stop engine. If fan is not running, stop engine and allow to cool. Check cooling fan for obstructions. Replace 30 amp cooling fan fuse.

ˇ Allow engine to cool. Check and clean area around radiator and hydraulic oil cooler for buildup of debris and grass.

ˇ Fill coolant overflow tank with a 50/50 mix of coolant and water.

ˇ Inspect cooling system for damage and repair. Fill radiator with 50/50 mix of coolant and water.

ˇ The engine oil pressure light (D) indicates the engine oil pressure is low. The indicator should light when the key switch is turned to the run position, and should go off once the engine starts. The warning beeper will sound when the lamp turns on.

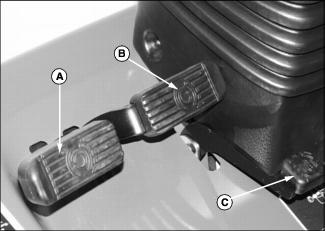

Using Hydrostatic Pedals

Using Forward Travel Pedal:

1. Push the forward travel pedal (A) down slightly to begin forward motion. Push the pedal down farther to travel faster.

2. Release the pedal to return to neutral and stop the mower

Using Reverse Travel Pedal:

1. Push the reverse travel pedal (B) down slightly to begin reverse travel. Push the pedal down farther to travel faster.

2. Release pedal to return to neutral and stop the machine.

Using Brakes

Using Master Brake Pedal

1. Push the master brake pedal (A) down to hold the machine stationary on a slope, or for an emergency stop. PTO will disengage when master brake pedal is depressed, and PTO switch will have to be recycled once brake is released to restart PTO.

Using Park Brake

1. Lock the park brake by pulling the park brake lock lever (B) upwards, and fully depressing the master brake pedal (A). The pedal should stay locked down.

2. Unlock the park brake by depressing the master brake pedal, and pushing the park brake lock lever down. Release the master brake pedal.

Using Turn-Brakes

The turn-brakes are used to change direction quickly within the width of the machine. Avoid using the turn-brakes in areas where turf damage is not acceptable. Turn-brakes will not turn machine if differential lock is engaged.

1. Depress the right turn-brake pedal (C) to slow or stop the right front wheel, while power is applied to the left wheel. The machine will turn to the right. Release the turn-brake pedal to resume driving in a straight line.

2. Depress the left turn-brake pedal (D) to turn to the left.

Using Differential Lock Pedal

The differential lock is used to help improve traction on slopes and on slippery surfaces. The front drive axle will lock so that the front wheels turn together.

IMPORTANT: Avoid damage! Use the pedal only when you need more traction. Do not lock the differential at high speed or make sharp turns when the differential is locked, or turf damage may result. |

1. Push the differential lock pedal (A) down with the left foot and hold it.

To unlock the differential:

2. The differential will stay locked as long as wheel rotation is unequal. Once the load on the transmission is equalized and reduced, the differential lock will disengage automatically.

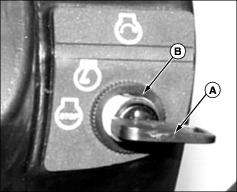

Using Fuel Shutoff Valve (Diesel Models Only)

NOTE: Close fuel shutoff valve when storing machine or when transporting on a trailer.

1. Open the engine cover. Locate the fuel shutoff valve (A) on the left side of the engine

ˇ To open the fuel shutoff valve:

Turn the handle so the pointer (B) is facing up as shown.

ˇ To close the fuel shutoff valve:

Turn the handle so the pointer is facing to the rear.

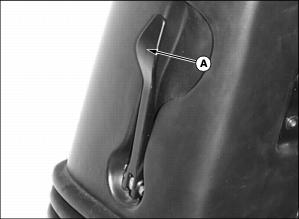

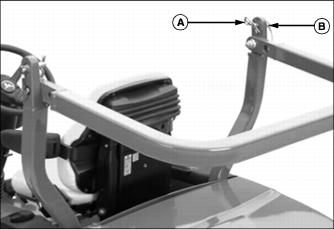

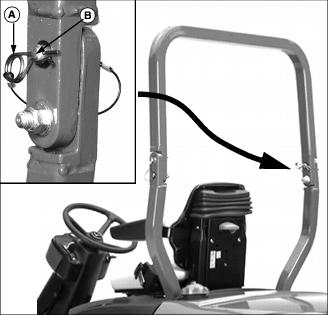

Lowering ROPS

1. Park machine safely. (See Parking Safely in the Safety section).

2. Remove spring pin (A) from drilled pin (B) on left and right side of ROPS.

3. Remove drilled pin from left and right side of ROPS.

4. Pull ROPS rearward to lower.

5. Install drilled pins and spring pins back into hole in ROPS to secure in place.

Raising ROPS

1. Park machine safely. (See Parking Safely in the Safety section.)

2. Remove spring pin (A) from drilled pin on left and right side of ROPS.

3. Remove drilled pin from left and right side of ROPS.

4. Push ROPS into upright position.

5. Install drilled pin into holes on left and right side of ROPS, and secure in place with spring pins.

6. Check the ROPS bolt torque if the ROPS is loose.

Raising and Lowering the Attachment

1. Turn off PTO. Raising an attachment will not stop the PTO; the attachment continues to run in the raised position.

To Raise Attachment:

ˇ Pull lift lever (A) rearward. Attachment will raise up until lever is released, or attachment reaches top of travel, whichever occurs first.

To Lower Attachment:

ˇ Push lift lever forward. Attachment will lower until lever is released, or attachment reaches the ground, whichever occurs first.

To Float Attachment:

ˇ Push lift lever fully forward until it latches into float position. Attachment will raise and lower as needed to follow contour of ground.

Starting Engine

NOTE: The engine will not start unless the PTO is off, and the master brake pedal is depressed.

1. Open the fuel shutoff valve (diesel models only).

2. Sit on the operator's seat. (Seat should spring down slightly so seat switch is actuated.)

4. Depress the master brake pedal if the park brake is not locked.

5. Push down the PTO switch to the off position.

6. Pull the throttle lever back to the slow idle position.

7. Model 1420 only: push the choke lever fully forward if engine is cold, or half-way forward if engine has been run and is still warm.

8. Turn the key switch to the on position.

9. Models 1435 & 1445 only: Wait for the engine preheat light to turn off.

IMPORTANT: Avoid damage! Do not overheat starter. Do not operate starter more than ten seconds at a time. Wait two minutes before trying again if engine does not start. |

10. Turn the key switch to the start position for no longer than ten seconds. Release key to run position after engine starts.

ˇ If starter engages, but engine does not start, wait two minutes and try again for no longer than ten seconds.

IMPORTANT: Avoid damage! Do not idle engine for long periods of time. Excessive idling can cause engine overheating, carbon build-up, and poor performance. |

11. Let engine run at half-speed position for two minutes to allow it to warm up before operating machine.

12. Model 1420: Pull choke lever fully back before operating.

Stopping Engine

1. Push PTO switch down to the off position.

2. Move throttle lever back to the slow idle position. Let engine run at low idle a few seconds.

4. Lower attachment to the ground.

5. Turn the key switch to stop position.

NOTE: Model 1420 only: The engine will continue to run for 1-2 seconds after key is turned to the off position. This is normal and prevents build-up of unburned gas in the exhaust system.

Transporting Machine

1. Push PTO switch down to the off position.

2. Lower the attachment to the ground.

3. If necessary to transport with the attachment raised, avoid hard braking, slopes, and keep transport speeds low.

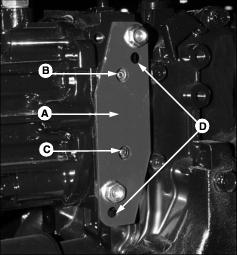

Moving Machine with Engine Off

IMPORTANT: Avoid damage! Transmission damage may occur if the machine is moved or towed incorrectly: |

1. Turn key switch to off position.

2. Push 4WD lever into forward position.

3. Open service hatch and locate the red plate (A) on the right side of the transaxle housing.

ˇ For pushing machine short distances in the forward direction, push in and release the top relief valve (B) with a small tool.

ˇ For pushing machine short distances in the reverse direction, push in and release the bottom relief valve (C) with a small tool.

ˇ For pushing machine longer distances in forward and reverse, remove the two M8 flange head nuts, and install plate to lower set of drilled holes (D). Install nuts.

6. Push machine slowly by hand, or using winch, using brakes when necessary.

7. Do not use another vehicle to push or tow mower at high speed.

8. If red plate was moved to the lower set of holes, move it back to original position.

Transporting Machine on Trailer

Be sure trailer has all the necessary lights and signs required by law.

2. Drive forward onto heavy-duty trailer with attachment raised.

3. Lower attachment down to platform of trailer.

4. Stop engine, remove key, lock park brake.

5. Close the fuel shutoff valve (diesel model only).

6. Fasten machine to trailer with heavy-duty straps, chains, or cables. Fasten rear straps to rear frame or axle. Fasten front straps around front transaxle. Both front and rear straps must be directed down and outward from machine.

7. Check that engine cover is closed and latched. Fold ROPS to avoid overhead clearance problems while on trailer.